Waterjet cutting

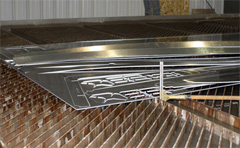

Waterjet cutting is capable of cutting stainless steel with high precision and high cutting speeds eliminating the need for costly recutting; this process uses jets of pressurized water as high as 60,000 pounds per square inch (PSI) and may include an abrasive additive such as garnet or aluminum oxide.

Steel products being cut with water jets are exposed to minimal tangential forces therefore work pieces require minimal or no clamping facilitating a quick setup – cuts can be started from any point along the contour. The jet creates equally narrow cutting gaps which limit wastage of material; this method's cutting abilities ensure a clean cut with a good burr free edge finish.

WaterJet Benefits

A high benefit of this waterjets is the fact that as a cold cutting method it does not affect the structural integrity of the metal, eliminating creation of heat affected zones (HAZ), material hardening and warping. Cutting stainless steel with traditional methods is a much slower and tedious process, not to mention expensive and inefficient when comparing to water jet cutting.

Cutting complex steel shapes is a reality with the use of

waterjets as the cold cutting method facilitates the cutting of virtually limitless shapes, detailed cuts and rapid hole drilling.

Another large benefit of water jet cutting is the ability to cut highly reflective metals as well as cutting materials of greater thickness, something that cannot be done through the use of laser.

The waterjet cutting apparatus can be mounted to a CNC controlled gantry or a robot allowing optimized utilization of CAD/CAM software for superior results, it can also be combined with other cutting technologies to produce bevelling, sharp corners – a feat hard to achieve with any other cutting method.

Ecofriendly and Sustainable

For those that strive to be environmentally friendly, the use of waterjets limits material wastage and eliminates the creation of dust saving precious resources. This benefits not only the environment but also the pocket of the client, as production costs decrease. No cutting oils or emulsions are used during the cutting process, eliminating the need of recycling and disposing of these chemicals.

The use of waterjets also builds a safer and healthier workplace, one where no heat or toxic fumes are generated.

Advancedprofiles has been providing their expertise in waterjet mild steel and stainless steel cutting services offering 18 feet by 36 feet of table space, 13 inch clearance from table to dual cutting heads, 100 Horsepower and redundant top works.

They are dedicated to providing consistent and accurate results, striving to stay on top of technology, managing their client's workflow and providing the best solutions to meet their clients.

If you would like more information on steel waterjet cutting visit us at

http://www.advancedprofiles.com/ or reach one of our representatives at (905) 695-1245.